Roman concrete was known as opus caementicium; and was made from volcanic dust mixed with lime

Ancient Romans built concrete sea walls that have withstood pounding ocean waves for more than 2,000 years. Now, an international team has discovered a clue to the concrete's longevity: a rare.

Quiz & Worksheet Roman Concrete Construction

The longevity of Ancient Roman concrete was a mystery to many researchers until 2014 when researchers came to a conclusion on its origin [9]. The Ancient Roman's concrete consisted of a mix of volcanic ash or also known as Pozzolana, lime, and water to make a mortar [13]. The mortar was then mixed with the aggregate, often chunks of rock, to.

SelfHealing Concrete What Ancient Roman Concrete Can Teach Us Hackaday

The question, then, was where the necessary heat came from to make those clasts. It had been thought that Roman concrete was created by combining water with a calcium compound called slaked lime.

recreating “ANCIENT CONCRETE” similar to what the romans used YouTube

The Nature of Roman Concrete 3 Concrete Vaulting during the Republic 3 Structural Behavior of Concrete Vaults 6 Roman Mathematical and Analytical Background 10 Materials, Transport, and Production 12 The Building Industry in Rome 18 The Innovations 21 2 CENTERING AND FORMWORK 22 Assembling the Centering 22 Removing the Centering and Formwork 26

How To Make Roman Concrete That Lasts More Than 2,000 Years...

One of the greatest examples of Roman concrete construction was the dome of the Pantheon, with its 43.4-m span. The vast system of aqueducts also made extensive use of hydraulic cement. This paper.

What Made Ancient Roman Concrete So Durable? YouTube

The cement in Roman concrete contains more aluminum and less silicon than modern concrete, which may be the key to the longevity of Roman concrete. This resulting calcium-aluminum-silicate-hydrate (C-A-S-H) is an exceptionally stable . binder. These natural substances formed structures (almost like cages) around sulide

Roman Concrete Construction

Roman concrete samples dating from the same time period (8), and correspond with the city's Roman occupation, which lasted through the fall of the empire. To investigate centimeter-, millimeter-, and submillimeter-scale compositional details of the mortar samples, we used SEM-EDS. Large-area elemental mapping of the freshly fractured surface of a

Roman Concrete Construction

Ancient Roman concrete has withstood the attack by elements for over 2,000 years. The basic construction tech-. with pozzolan, the calcium hydroxide enters the atomic holes to make a concrete gel which expands, bonding pieces of rock together. The fine powder condition of the pozzolan provides a large surface area to enhance the

Roman Concrete Construction

properties of Roman concrete and 3-D modeling from drone images was a larger exercise in finding connections between different fields of study. It's no accident that students chosen to participate.

Roman Concrete Construction

ABSTRACT: The concrete composites used to realize the m. onumental structures of Imperial Rome are re-markable engineering materials. While the end. urance of intact constructions such. as the Pantheo. n evinces the concretes' durability, such. durability mostly serves to. preserve the mechanical prop.

Aqua Clopedia, a picture dictionary on Roman aqueducts Roman concrete / opus caementicium

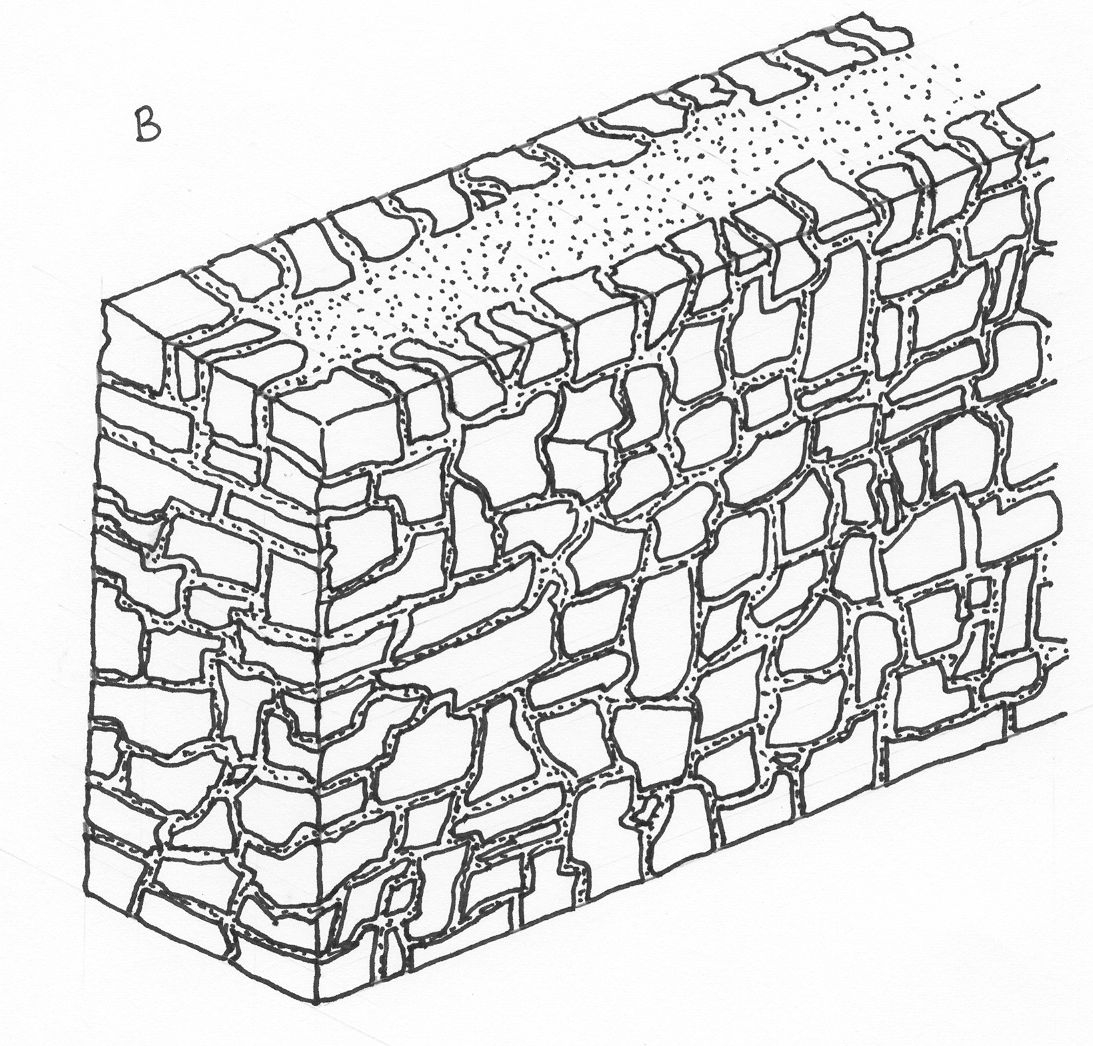

Roman concrete, like any concrete, consists of an aggregate and hydraulic mortar, a binder mixed with water that hardens over time. The composition of the aggregate varied, and included pieces of rock, ceramic tile, lime clasts, and brick rubble from the remains of previously demolished buildings. In Rome, readily available tuff was often used.

How seawater strengthens ancient Roman concrete UNews

THE SECRET ROMAN RECIPE. Other "secrets". • Rigid quality control, • Low water to cementitious materials ratio, and • Expert placement and compaction. • the Romans had no knowledge of present-day chemistry, • they nonetheless knew how to distinguish a good quality lime and other concrete ingredients through empirical observation.

Session no. 2, 2012 Roman Concrete, by Ross Nightingale

One of the most renowned of the Roman contributions to building technology was the development of concrete, which affected the vaulted roofing schemes, and bridge and harbor construction. The production of bricks in imperial Rome is a prime example of technological advance that resulted in increased organization rather than innovation.

Back to future with Roman architectural concrete

Masic and his colleagues were trying to re-create an ancient Roman technique for making concrete, a mix of cement, gravel, sand and water. The researchers suspected that the key was a process.

Drilling Into The Secrets Of Roman Concrete Science Friday Roman concrete, Science friday, Drill

The three components of Roman concrete were aggregate, mortar and facing. The aggregate was composed of stones, terra cotta, or tiling and represented the bulk of concrete constructions. In fact, the Latin name for Roman concrete is opus caementicium, after caementa — rough, unhewn quarry stones that reminded the Romans of the fist- sized.

How To Make Roman Concrete That Lasts More Than 2,000 Years… Roman concrete, Concrete, Roman

The Romans developed new architectural forms such as barrel vaults and domes, based in part on the Etruscan arch. Concrete domes were cast on top of centering form-work (De Camp 1980), as shown in Fig. 3. The weight of domes was reduced by casting empty amphorae into the concrete (White 1984, p. 206).